Inventory management often feels like a never-ending chase—tracking down misplaced items, manually updating transactions, and conducting tedious audits. RFID technology changes this game completely, bringing real-time visibility and accuracy to your operations. But what exactly makes RFID technology such a game-changer, and why should you consider integrating it into your inventory management processes?

Let’s explore three powerful features of RFID and how they transform inventory management.

1) Easily Locate Items: Think Geiger Counter for Your Inventory

We've all been there: urgently looking for a specific item in a huge warehouse or busy stockroom. Traditional methods can waste hours of precious time. RFID simplifies this dramatically.

Handheld RFID readers function similar to a Geiger counter, using audible and visual cues right to guide you directly to the item. As you approach your target, the signal intensifies, making item location quick, intuitive, and painless.

Imagine needing to locate an urgently needed critical spare part within a large warehouse or identifying a misplaced shipment on a crowded loading dock. RFID allows workers to rapidly find these items within seconds, significantly boosting operational efficiency and reducing downtime.

Another capability of RFID technology is the ability to locate any item of a given type, not just an items unique identifier. Using more advanced RFID application software, filters can be applied to locate items by status or type, like expired or recalled materials that posses an audit or safety risk, or the nearest pair of jeans of a specific style that the customer up front is waiting for!

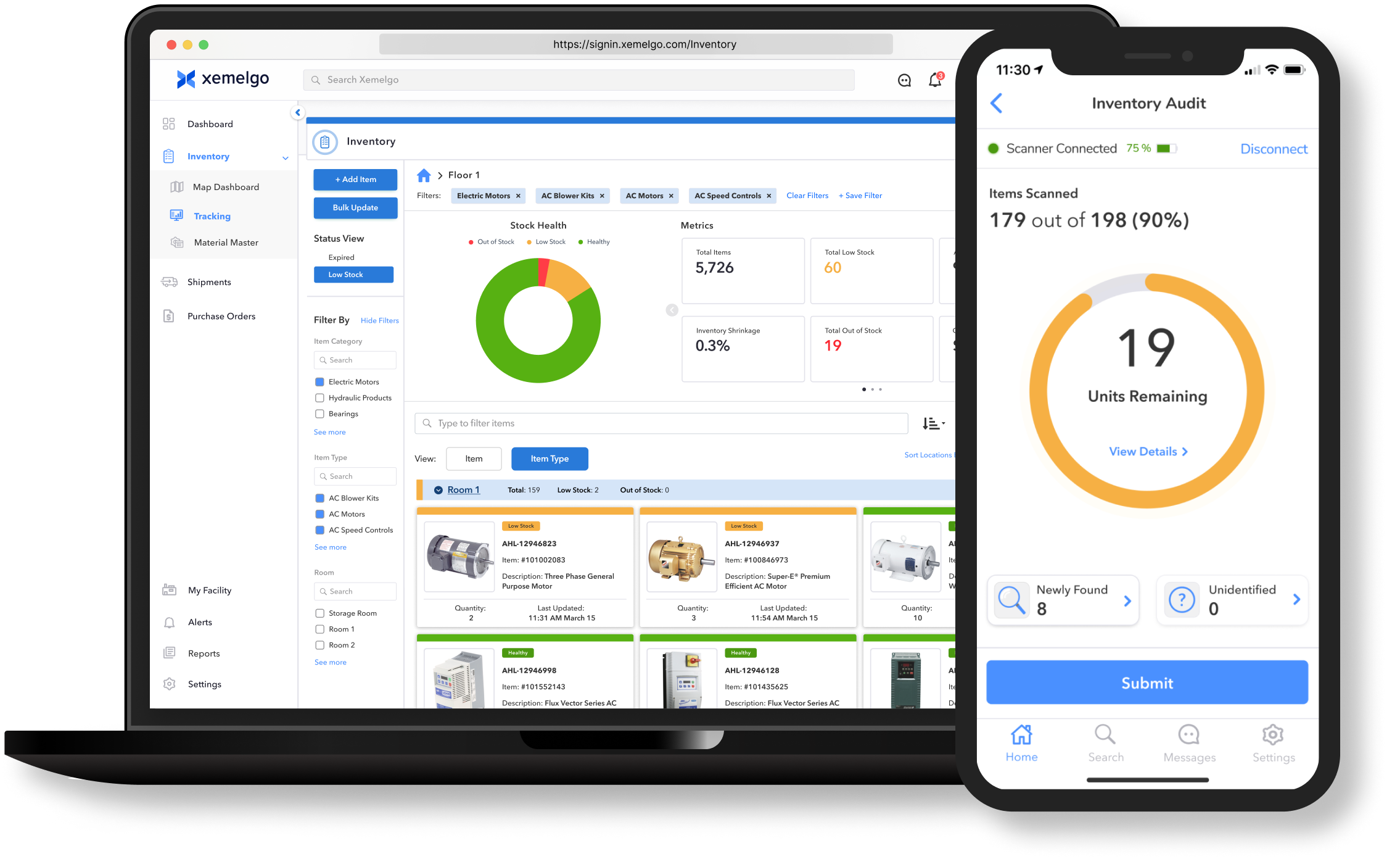

Some RFID-enabled software platforms like Xemelgo even provide visual maps and real-time updates on item locations, giving workers immediate insights into inventory whereabouts, further speeding up the locating process.

See how Good American keeps inventory accurate and finds items fast with Xemelgo—delighting customers and driving sales.

2) Lightning-Fast Cycle Counting: Audit Thousands of Items in Seconds

Anyone who’s spent a weekend or shutdown doing manual inventory audits knows the pain: it’s tedious, disruptive, and error-prone. RFID transforms cycle counting into a fast, reliable, and even fun task.

RFID readers can scan thousands of tagged items in seconds—no line-of-sight or manual handling required. Compare that to barcodes, where each item must be physically seen and scanned. With RFID, cycle counts that used to take days now take minutes.

This speed makes frequent, even daily, cycle counting a reality. And with accurate, up-to-date inventory data, companies benefit from better demand planning, fewer stockouts, increased revenue, and more confident decision-making.

Did You Know? Each RFID tag carries a unique EPC (Electronic Product Code), identifying individual items—not just SKUs. Think of it like the difference between knowing you have “milk” in the fridge versus knowing which carton, from which lot, and when it expires.

Discover how Hisco uses handheld RFID scanners to rapidly audit supplies and chemicals in their customer's grab-and-go stockrooms—boosting accuracy and saving time.

3) Automate Transactions: Hands-Free Inventory Updates

Imagine inventory that updates itself. That’s exactly what RFID enables—automated tracking of item movement across your facility, without manual scans or data entry, significantly reducing errors and labor costs.

As tagged items move past RFID readers at checkpoints—receiving docks, stock locations, or outbound lanes—readers automatically detect them and update your ERP or WMS in real time. No human input required. This real-time integration ensures your inventory data remains consistently accurate, providing immediate visibility into stock levels and item locations.

Whether you're receiving pallets, picking items for eCommerce orders, or shipping finished goods, RFID ensures inventory records stay accurate and up to date. It’s also ideal for tracking returnable containers and ensuring the right products are loaded on the right truck.

This automation minimizes human error, eliminates paper-based processes, and frees your team from repetitive scanning tasks—so they can focus on more strategic work.

Learn how aerospace manufacturer SEKISUI uses overhead RFID readers to automatically track parts across their production lines—improving visibility and efficiency.

Real-World Impact of RFID

RFID consistently delivers measurable results across retail, manufacturing, and logistics:

- Inventory accuracy consistently above 99%

- Dramatically reduced search times

- Significant cuts in labor costs associated with inventory tasks

Retailers leverage RFID to avoid stockouts, enhance customer satisfaction, and increase revenue. Distributors leverage the technology to validate order accuracy, replenish proactively, and automate transactions from receipt to shipment. Manufacturers rely on RFID to streamline supply chains, effortlessly manage compliance, and accurately track critical components.

Enhanced inventory visibility from RFID also helps businesses improve on-time deliveries, reduce waste, boost product availability, and significantly reduce shrinkage and loss.

Check out customer stories on our resources page for more real-world examples.

Getting Started with RFID

Adopting RFID doesn’t need to be a science project. Clearly defining your inventory challenges and specific goals—like reducing search times, automating inventory updates, or speeding up cycle counts—helps identify the right RFID tags, readers, and software to meet your needs.

At Xemelgo, we leverage our robust ecosystem of technology and VAR (Value-Added Reseller) partners to deliver complete, turnkey RFID solutions. Our partnerships ensure your RFID deployment is practical, scalable, and easy to implement, providing immediate results without complexity.

The Essential Role of RFID Software

RFID software is at the core of successful RFID implementations—it’s what your team will use and rely on day in and day out. While hardware captures the data, it’s the software that turns that data into action.

Modern cloud-based platforms like Xemelgo deliver intuitive interfaces, real-time visibility, and seamless integration with ERP and MES systems. They process live updates, track historical trends, and trigger automated alerts and visualizations to drive smarter, faster decisions.

The best RFID software also stands out with dependable live support, clear documentation, and easy device management—making it simple to scale, sustain, and build upon your success.

Choosing the right platform doesn’t just manage tag data—it streamlines operations, unlocks ROI, and ensures long-term project success.

Take Control of Your Inventory

With automated transactions, effortless item location, and lightning-fast auditing capabilities, RFID technology dramatically improves inventory management—cutting costs, boosting operational efficiency, and increasing accuracy.

Ready to transform your inventory management?

Visit our RFID Inventory Management Software page to learn more or book a consultation to discuss your specific needs with our RFID experts today.